Sarjapur Road, Bangalore, Karnataka

Pre Engineered Building Systems

Pre Engineered Buildings (PEB) are the buildings which are engineered at a factory and assembled at site. Usually PEBs are steel structures. Built-up sections are fabricated at the factory to exact size, transported to site and assembled there with bolted connections. This type of Structural Concept is generally used to build Industrial Buildings; like –Railway / Metro Stations, Warehouses etc.

The adoptability of PEB in place of Conventional Steel Building design concept resulted in many advantages, including economy & easier fabrication. These building structures can be finished internally to serve any functions i.e., actually help in low rise building design. Examples of PEB Buildings are warehouses, Canopies, Factories, Bridges etc.

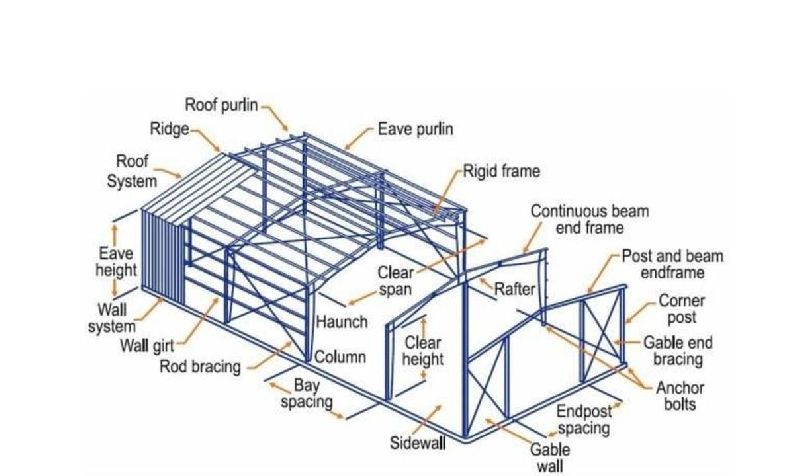

Components of PEB :

- Pre Engineered Buildings consist different steel structural members which are:

- Primary Frames

- Secondary Structural Elements: Cold Formed Members, which can be in different shapes like “Z”, “C” etc. In general known as “Purlins”.

- Roof & Wall Panels : Tin shades & Curtain Wall made of Glass & Roll-formed steel sheets usually comes in this category

- Sandwich Panels: Sandwich Panel is made of three layers, in which a non-Aluminum Core is inserted between two aluminum sheets.

- Other Accessories: Bolts, Insulation, etc.

Advantages of PEB :

- There are many advantages of Pre Engineered Buildings, which are as follows,

- Quality control is the main advantage as all the structural member are engineered beforehand, standards of different codes also taken into consideration & these components are made in factory under the supervision of Quality Control Engineer.

- Lower cost due to the saving in design, manufacturing and on site erection cost.

- Minimizing time of construction due to the use of software for design of the structural components.

- Low Maintenance due to use of standard quality of paints over steel members , which increases the ability to withstand & finally the maintenance cost will be low as compare to conventional steel building.

- Quick Erection, as all the members are Pre Manufactured & skilled labor is used for connections of different components.

- Warranty on PEB, mostly warranty period of 20 years given by manufactures for PEB.

Disadvantages of PEB :

- Although PEB have many advantages in the field of Industrial structure but still there are some demerits of Pre Engineered Buildings, which are as follows,

- Rusting / Corrosion Sensitive, as if the quality of steel used or paint used for coating of steel members is not of good quality , then it can damage the structure and thus reduces the life of structure.

- Insulation Cost, as insulating the building to an agreeable benchmark will furthermore add to your construction costs.

- Appearance, Steel Sections can be unattractive when left exposed.

Contact Us

Top Edge Consulting

Address : ., Sarjapur Road, Bangalore, Karnataka - 562125, India

Mobile : +91-9986027280, +91-9845004914

Phone : ++91-80-29511892

Show Email Address : topedgeconsulting.blr@gmail.com

For Building Interiors : www.techomedecor.com